Product Specifications

- 100% FRP composite material

- No layering, no bonding, no surface grit coating

- Hand molded

- Durable and long-lasting

- Superior glow-in-the-dark performance

Safety Step anti-slip covers eliminate slips, trips and falls in any industrial or commercial environment by ensuring maximum traction for workers and pedestrians in numerous applications where there are stairs, ladders, or walkways.

Worldwide, our products and custom applications are currently providing safer footing every minute of every day for thousands of people.

Safety Step anti-slip covers are manufactured entirely by hand in a unique multi-step fabrication process, then trimmed and cut to size. By incorporating the separate elements into one seamless fiberglass composite material, we build the strongest and most durable product available on today’s market.

A base mix of fire-retardant polyester resins is interspersed with layers of immensely strong interwoven glass fiber. The color pigment is floated throughout the full thickness of the material, ensuring the color never wears off or becomes unsightly. The fused alumina anti-slip grit is then forced under pressure into the base mix while it is still wet, followed by a final layer of resin over the top of it all. This entire composite mix is then cured at optimum temperatures until fully hard.

FRP does not dent, corrode, rot, delaminate, or support bacteria growth. It has a high strength to weight ratio being several times higher than steel on a weight-to-weight basis. It demonstrates a very high resistance to UV exposure and other environmental conditions, is highly resistant to chemical attack, and has an indefinite life span.

Other manufacturers adopt a layering or bonding method where an anti-slip coating is bonded to a preformed base such as steel or pultruded material. This method sets up a weak point where the two dissimilar components meet. This weak point will be further strained by stress set up within the product through movement associated with normal use or thermal expansion and contraction. Such a bonding method also has a low tolerance to impact and typically the top coating will peel away from damaged areas.

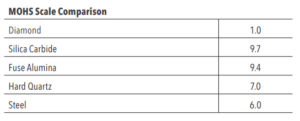

The super tough abrasive grit used to form the rugged surface on Safety Step anti-slip covers is one of the hardest compounds known. Fused alumina grit is bound within the glass reinforced body of all Safety Step covers, presenting a top surface with almost diamond hard characteristics.

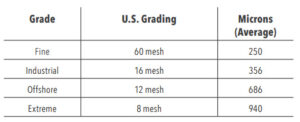

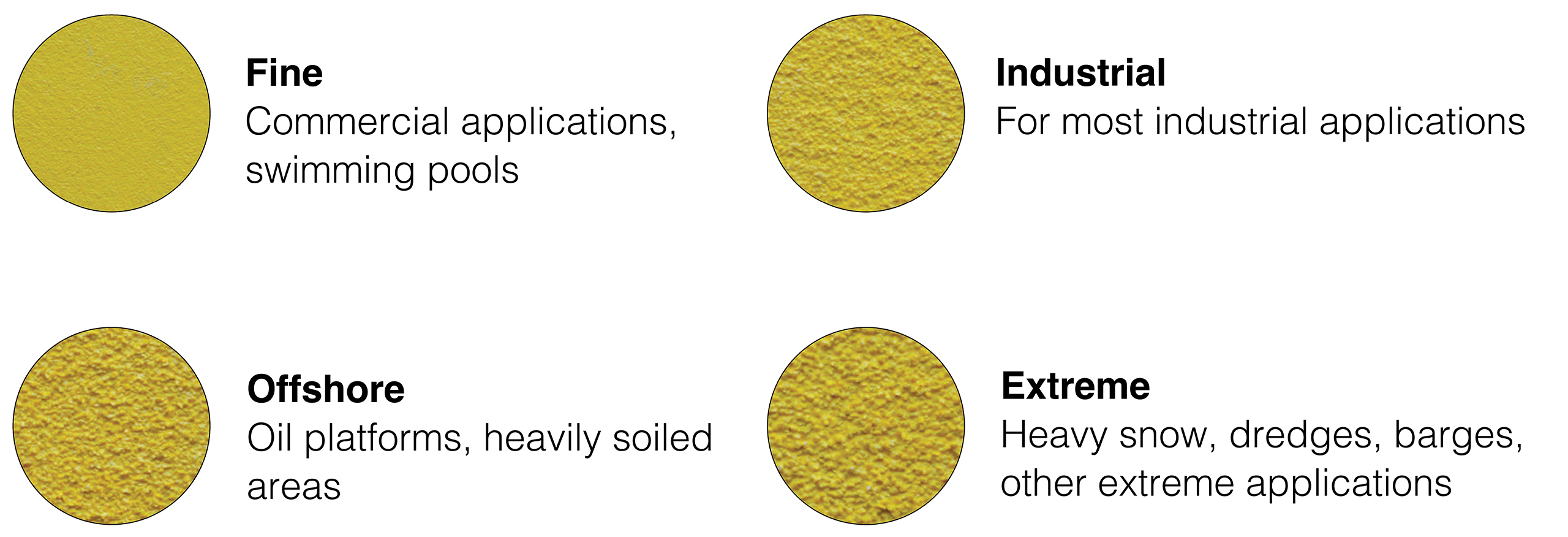

As different manufacturers have different names for each grade of their anti-slip material, the following comparisons of grading may be used for Safety Step:

Safety Step anti-slip covers come in four grit sizes to suit any application:

Color matching to RAL classic color system is available on request.

Color matching to RAL classic color system is available on request.A fully embedded, photoluminescent strip can be included on all Safety Step products to provide glow-in-the-dark capability and critical visibility of emergency evacuation and egress pathways in any facility.

Glow-in-the-dark capability can be included with Safety Step anti-slip products to provide extremely long-lasting definition of step edges, ladder rungs, and directional indicators in low and no-light situations. A fully embedded, photoluminescent strip shows green in daylight and glows bright green/yellow in darkness and will glow for a minimum of twelve hours once fully charged by a light source. These treatments provide critical visibility of emergency evacuation and egress pathways in any facility.

The strontium aluminate pigment which is incorporated in all Safety Step photoluminescent products glows more than ten times brighter than traditional glow products made using zinc sulfide. The pigment is charged by exposure to light sources such as fluorescent, incandescent, or unfiltered UV light and will emit luminescence after the activating light source is unavailable. This material is non-toxic and non-radioactive.

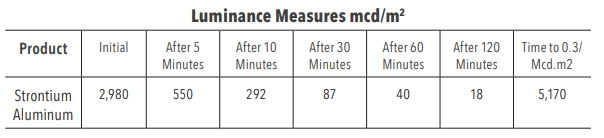

The table below indicates the luminescence decay timelines of our glow-in-the-dark product applications.

Luminescence performance has been measured and charted from initial darkness to a condition of 0.3 milli-candelas per square meter, which is the visibility threshold of the human eye.

The test samples were exposed to 1,000 lux illumination from a 150-watt xenon light source for five minutes immediately prior to the initial luminescence measurements.

Safety Step products have coefficient of friction (COF) test results produced from the three internationally most widely accepted slip meters:

- The Brungraber Mark II

- The English XL VIT

- The British Pendulum Slip Tester

Our products have been tested with the above apparatus and found to comply with and exceed the requirements of the following standards:

- ASTM F1677

- ASTM F1679

- NFPA 1901

- DIN 51130

- AS/NZS 4586

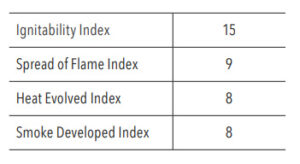

Independent laboratory testing has confirmed that Safety Step products will exhibit the following flammability characteristics:

Safety Step Step Covers provide both a smart look and reliable anti-slip protection, requiring minimal maintenance to keep them in top condition. Basic cleaning can be accomplished with steam or water along with mild detergents, citrus cleaners, “green” solutions—just avoid strong solvents. For more stubborn soilage and snow or ice buildup use synthetic brushes/brooms; shovels made of plastic or composite should be used for heavier deposits. Do not use steel shovels and scrapers, or wire brushes and brooms.